Optics development

From LED selection to series production

Development of optical components

From selecting the appropriate LEDs, defining target objectives, and developing application-specific optic designs to manufacturing and assembly: we accompany you throughout your project, providing end-to-end service. Leveraging state-of-the-art software, we conduct both optical and thermal simulations of the most complex assemblies.

Optical Design

Optimization and Final Configuration of the System According to the Specification

Prototyping

Prototyping, Evaluation, and Presentation of the System

Series production

Manufacturing of tools and process optimization for series production

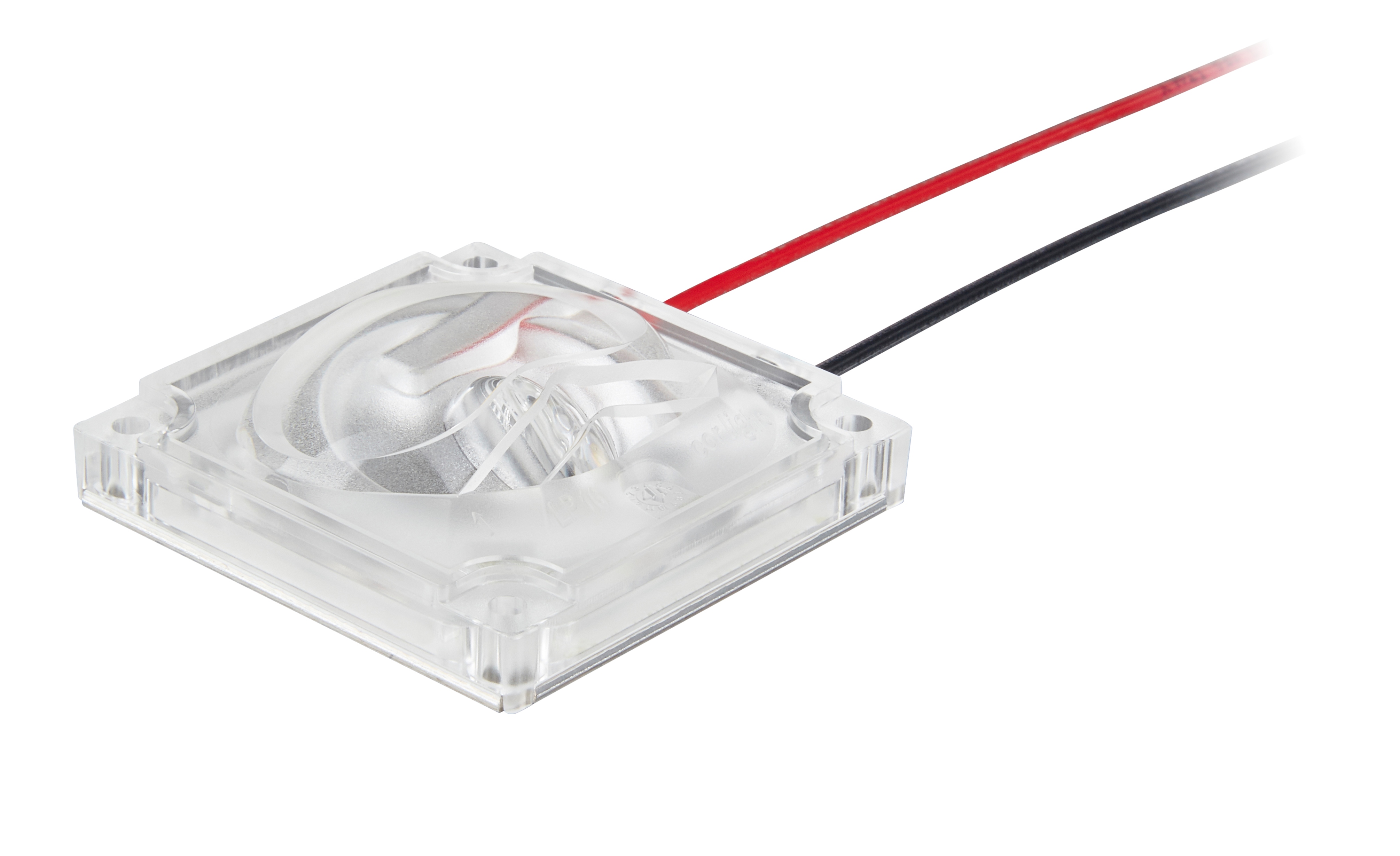

We support you with innovative solutions at the cutting edge of technology. Our developments are utilized for applications across various industries—particularly, our expertise lies in the development of freefrom optics. This technology enables us to realize custom tailored light distributions with low costs and high optical efficiencies in the smallest possible footprint.

Moreover, we are the right partner when it comes to color mixing—whether it’s colored RGB(W) applications or dynamic tunable-white applications where color uniformity must meet the highest standards. Additionally, we can design and optimize spot lenses with TIR technology, which provide maximum efficiency and light intensity, as well as complex light guide systems, and bring them to series production readiness.

Our Services Include

Selection of possible light sources

Analysis of optical systems using state-of-the-art ray tracing software

Thermal analysis, modeling, and optimization using thermal CFD simulations

Measurement of optical systems and comparison with simulations and target applications

Creation of illumillumination concepts

Calculation of custom freeform lenses and reflectors

Virtual prototyping and generation of simulated photometric data

Transition to series production of optics, LED modules, and luminaire components

Optical design and layout of illumination optics

Design of TIR spot lenses, light guides, and color mixing optics

Creation of functional prototypes

Mass production of lighting units, boards, lenses, and luminaires

1. Concept Study

Conducting a concept and feasibility study provides a cost-effective and efficient way to evaluate the feasibility of your project idea.

An initial kick-off meeting allows us to collaboratively establish the specific requirements of your application. Based on this information, we create a detailed specification and subsequently develop various illumination and optics concepts for you. This step includes research into suitable LEDs, the development of conceptual optics, and the analysis of the designs in terms of their performance.

The goal of the feasibility study is to present you with different design concepts. To achieve this, we compile a comprehensive report containing concept descriptions, sketches, as well as intensity and illuminance distributions, along with additional photometric data. A detailed description of the analyses and a list of the advantages and disadvantages of each concept enable you to select the optimal solution for your needs.

2. Optical Design

In this development phase, the concept chosen by you is implemented specifically for your product according to your specifications.

Based on your feedback, optical specifications are initially created or adjusted. The design of the optical system is optimized using state-of-the-art calculation and simulation software to maximize its optical performance. Drawing upon our extensive experience in manufacturing high precision optical components, we ensure seamless manufacturability. If desired, all other necessary components of the product, such as mechanical connections, the circuit board including layout, and the heat sink, are also designed and optimized for the highest technical performance in this project phase.

At the conclusion of this phase, you will receive analyses of the developed optical system in your component, the geometry of the component, and photometric data if requested.

3. Prototyping

The prototype phase encompasses all necessary steps for manufacturing an initial product prototype. We utilize versatile resources for single or batch production:

- 3D printing of optical prototypes

- Injection molding with prototype tools

- Precision turning of optical elements using ultra-precise diamond turning machines

- Milling of individual optics and heat sinks

- Creation and assembly of prototype circuit boards

The manufactured prototypes are optically measured and carefully analyzed as needed. Further tests such as thermal measurements, standardized IP and IK tests, aging, and corrosion tests can also be conducted upon customer request. At the end of this phase, you will have your customized product prototype in hand.

4. Mass Production

In this final development phase, we handle the series transition of the optical components and all other required components of the lighting product for you.

This includes communication and coordination with potential suppliers as well as the creation and handover of final CAD data for series production. Subsequently, we accompany the process optimization and monitor series production, ensuring seamless quality control.

At the end of this final phase, you will receive your finished and customized lighting product.